Beyond Limits: The Fusion of 3D Printing & Custom Displays

Combining the strength of traditional craftsmanship with the unlimited design freedom of additive manufacturing.

Why Choose 3D Printed Hybrid Displays?

At Custom Display Works, we are revolutionizing the way brands showcase their products. While traditional manufacturing handles the heavy lifting, our advanced 3D printing technology adds the “wow” factor.

By integrating 3D printed components with our standard metal, wood, or acrylic racks, we can produce intricate shapes, complex textures, and hyper-customized branding elements that traditional molds simply cannot achieve cost-effectively.

Unlimited Design Freedom

Break free from geometric limitations. Create organic shapes, intricate lattice structures, and bespoke holders that perfectly fit your unique product contours.

Rapid Prototyping & Speed to Market

Need a sample in days, not weeks? 3D printing creates physical prototypes quickly, allowing you to validate designs and launch campaigns faster than your competitors.

Cost-Effective Low Volume Production

Say goodbye to expensive mold fees (tooling costs). For limited editions, seasonal promotions, or test markets, 3D printing offers a budget-friendly solution for small production runs.

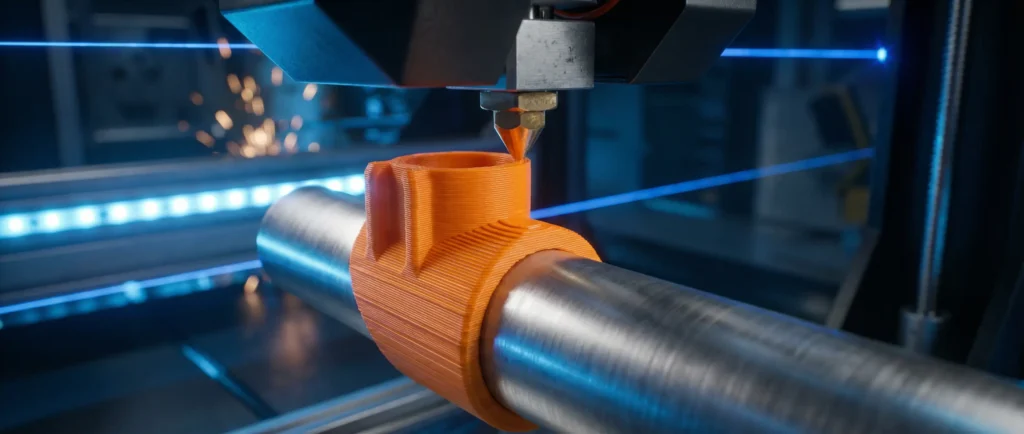

The Hybrid Advantage

We use durable materials (steel/wood) for the structural frame and high-precision 3D printing for detail-oriented parts (headers, product holders, logos). This ensures your display is both sturdy and visually stunning.

Where 3D Printing Enhances Retail Displays

Custom Product Holders

Perfectly contoured cradles for electronics, cosmetics, or eyewear that prevent wobbling and look premium.

Dimensional Logos & Branding

High-relief, multi-textured 3D logos that pop out from the header board.

Complex Joints & Connectors

Smart modular parts that allow for unique assembly angles not possible with standard tubing.

Seasonal & Pop-up Displays:

Unique, eye-catching props for short-term retail campaigns.

How it works--- From Concept to Reality

- Consultation: Share your vision and product specs.

- 3D Modeling: Our engineers design the hybrid structure

- Prototyping: We print a sample for your approval

Production: We combine printed elements with the main structure for final assembly.