Revolutionizing Retail: The Role of 3D Printing in Mixed Material Display Racks

In the fast-paced world of retail, the “first glance” is everything. Brands are constantly searching for display solutions that are not only durable but also visually arresting. At Custom Display Works, we believe the future of retail design lies in the intelligent combination of materials.

While we specialize in traditional craftsmanship using metal, wood, and acrylic, there is a game-changer in our workshop: 3D Printing (Additive Manufacturing).

In this post, we explore how integrating 3D printed components into mixed material display racks is solving complex design challenges and speeding up the journey from concept to shop floor.

1. Rapid Prototyping: Seeing is Believing

Before we cut expensive hardwood or weld steel frames, we need to be sure the design works.

Traditional prototyping for mixed material racks can be costly and time-consuming, often requiring multiple molds or tooling adjustments. With 3D printing, we can produce a physical scale model or full-size specific components (like a complex joint or bracket) in a matter of hours.

The Benefit to You:

Speed: Reduce product development time by weeks.

Accuracy: Test the fit and function of different materials (e.g., how an acrylic shelf sits on a 3D printed bracket) before mass production.

2. Solving the “Connection” Challenge

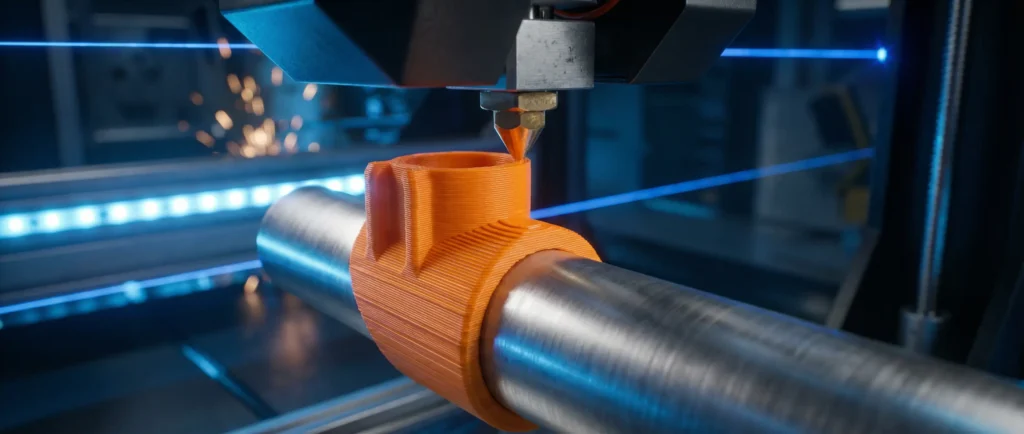

The hardest part of building a mixed material display—for example, combining sleek metal tubing with rustic wooden shelving—is the connection point. Standard off-the-shelf connectors can look clunky and cheap.

3D printing allows us to design and manufacture custom connectors and joints that are invisible or stylized to match your brand. We can print complex geometries that hold metal, wood, and plastic together securely without visible screws or welding marks.

Example: Imagine a display stand featuring bamboo uprights and acrylic shelves. We can 3D print a custom friction-fit joint that seamlessly marries the two materials, creating a clean, modern look that traditional manufacturing cannot easily achieve.

3. Cost-Effective Customization for Small Batches

Not every client needs 10,000 units. Sometimes, you need 50 exclusive displays for a pop-up store or a seasonal campaign.Creating injection molds for plastic parts is incredibly expensive and only makes sense for mass production. 3D printing eliminates the need for molds entirely. We can print intricate branding elements, logo toppers, or product holders for a limited run of displays at a fraction of the cost.

4. Complex Textures and Branding

3D printing allows for a level of detail in texture that is hard to replicate with wood or metal.

Logos: We can print 3D dimensional logos that pop out from the display header.

Textures: We can mimic the texture of leather, woven fabric, or geometric patterns on specific parts of the display rack to enhance tactile engagement.

By combining these printed elements with the structural integrity of metal and the warmth of wood, your display becomes a piece of art rather than just a storage unit.

Conclusion: The Perfect Hybrid

At Custom Display Works, we don’t just use technology for the sake of it; we use it to enhance craftsmanship. 3D printing doesn’t replace our metal fabrication or woodworking skills—it elevates them.

By utilizing 3D printing for complex joints, prototyping, and intricate details, we deliver mixed material display racks that are stronger, smarter, and more stylish.

Are you ready to elevate your retail presence?

Whether you need a sleek POS display or a robust floor-standing rack, let us show you how a hybrid approach can bring your vision to life.